Welcome to our store!

Customer Support 00966 545 154 351

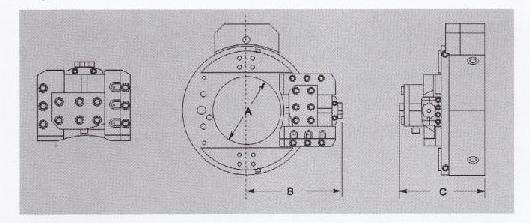

The

ID Mounted beveling operation utilizes an expandable mandrel which is slid into

the open end of the pipe. Draw nut is

tightened, which expands the mandrel blocks up a ramp and against the ID

surface for positive mounting, self centered and squared to the bore. As the

tool bit is fed in to the material from the end, bevel is produced which

confirms to the angle predetermined by the angle ground in to the bit. Bits are

available for practically any material or beveling required, and bits can be

custom made for any form tooling operation.

Features

u

Cold Beveling

u

Fast, Precision On-site Beveling

u

Minimal Axial and Radical clearance

u

Light weight and compact design

u

Easy set-up & robust operation

u

Electric at Pneumatic drive

ID

MOUNT END PREP BEVEL